The movement speed of the pneumatic cylinder is mainly determined by the needs of the working mechanism. When the demand is slow and stable, gas-liquid damping pneumatic cylinder or throttle control should be used. The method of throttling and speed regulation is: it is recommended to use the exhaust throttle valve for the horizontal installation of the thrust load; it is recommended to use the intake throttle valve for the vertical installation of the elevator load; check the basic cycle of the cycle. The buffer pneumatic cylinder can be used to avoid the impact at the end of the stroke. When the pneumatic cylinder is not high, the buffer effect is obvious and the speed is not high. If the speed is high, the terminal will be hit frequently.

How to judge the common faults of the pneumatic cylinder and learn the mechanism of pneumatic cylinder maintenance?

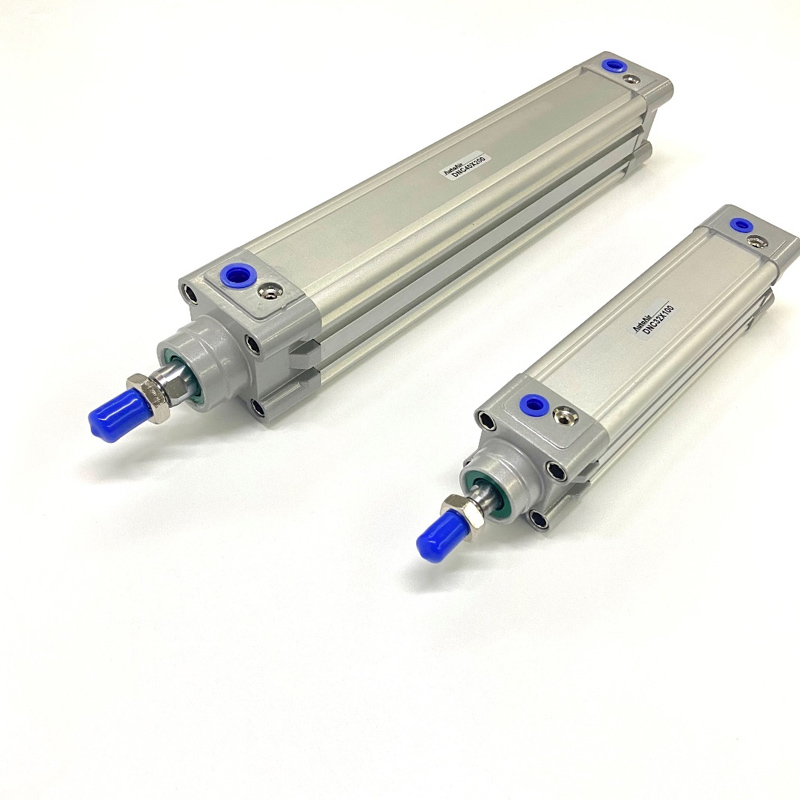

The basic composition and working principle of the pneumatic cylinder:

Taking the single-piston-rod double-acting pneumatic cylinder used in the pneumatic system as an example, the typical structure of the pneumatic cylinder is explained, which includes the pneumatic cylinder tube, the piston, the piston rod, the Pneumatic Cylinder Kit , the rear end cover and the seal. A double-acting pneumatic cylinder is divided into two chambers by a piston. Having a piston rod cavity is called a rod cavity, while no piston rod cavity is called a rodless cavity.

When the compressed air enters from the rodless cavity, there is a sucker rod cavity for exhaust, and the pressure difference between the two chambers of the pneumatic cylinder forces the force on the piston to overcome the resistance load to push the piston to move, making the piston rod extend; When there is a rod cavity, the piston rod is retracted and there is no sucker rod cavity exhaust. If there is a sucker rod cavity and a non-rod cavity between the air and exhaust, the piston is reciprocating. The working principle of the pneumatic cylinder: the compressed air makes the piston move, changes the direction of the intake port, and changes the movement direction of the piston rod.

Judgment and maintenance technology of common faults of pneumatic cylinder:

1. Good Pneumatic cylinder:

Hold the air hole with your hand, then pull the piston shaft with your hand. When you pull it, it has a huge reverse force. When it is released, the piston bounces back to its original position. Pull out the push rod and plug the air hole in. It also has a huge counterforce when pressed manually. The piston will automatically bounce back.

2. Bad pneumatic cylinder:

When pulling, there is no resistance and no small force. When the piston is released, there is no movement or slow motion of the piston, when it is pulled out, it has the opposite force, but when it is pulled continuously, it slowly descends. In times of stress there is no stress or stress, but less stress.

Generally, the magnetic switch is not easy to break, but we often have the phenomenon that the actual magnetic switch does not work and has no signal output. This is because the installation position of the magnetic switch changes, resulting in the induction magnet of the pneumatic cylinder, which requires us to often Check for tightness.

We do not recommend maintaining the pneumatic cylinder, but sometimes for emergency use, we suggest you can do simple repairs for air leaks, no movement, slow motion or airflow.

First, use the retaining ring to clamp the rear pneumatic cylinder spring (screw) to remove, remove the pneumatic cylinder piston, there will be a rubber band on the top of the piston, the general pneumatic cylinder action, the movement is slow, or the mixing is because the rubber band is worn too much, remove the rubber band, and then install The new rubber band, clean the pneumatic cylinder block, make sure that the pneumatic cylinder block of the two intake ports and the inner wall is good to rub a small amount of pure butter and the rear pneumatic cylinder and spring. Generally, after such repairs, the service life of the pneumatic cylinder will be extended for one year. to two years.

1. Store the equipment and keep it clean.

2. Do not overload and use equipment.

3. Solve problems patiently without violence.

4. Precise parts should be kept strictly, and blunt or sharp objects should not be used to hit the spreader;

5. The wearing parts are well made and the drawings are updated quickly, which can greatly shorten the maintenance time.

6. Observe the operation of the equipment to prevent equipment failure. In the process of internal and external leakage of the pneumatic cylinder, the main reason may be due to the eccentricity of the piston rod during the installation process, the insufficient supply of lubricating oil, the wear and tear of the sealing ring or the seal, and the impurities caused by the pneumatic cylind

Post time: Jun-21-2022