Commonly used are MAL aluminum alloy mini air cylinder (made by aluminum tubes models, MA stainless steel mini cylinders, DSNU mini cylinders, CM2 mini cylinders, CJ1, CJP, CJ2 and other miniature mini cylinders.

The main features and advantages of mini Pneumatic cylinders,

1. Mini Pneumatic cylinder bore is generally divided into 6.10.12.16.20.25.32.40mm.

2. The structure is compact in size, and the front and rear threads are installed and fixed, which can effectively save installation space and can be suitable for high-frequency use requirements

3. A variety of cylinder installation accessories are available for selection, which is flexible and changeable.

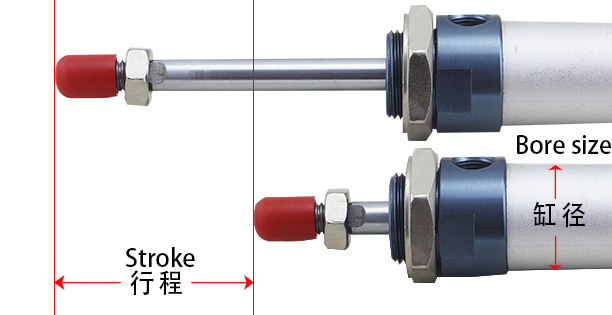

How to select the standard air cylinder? First to confirm the bore and stroke

Stroke is the error distance between the extension and retraction of the piston rod. Some people will calculate the stroke by exposing the cylinder itself. This is all wrong. The pneumatic cylinder diameter is the diameter of the inner wall of the cylinder. Generally, the outer diameter can also be used to estimate the size of the inner diameter. Under the same air pressure, the larger the cylinder diameter, the greater the output.

The functions of the commonly used mini pneumatic cylinders in China are the same, the main difference is the appearance, installation size and model;

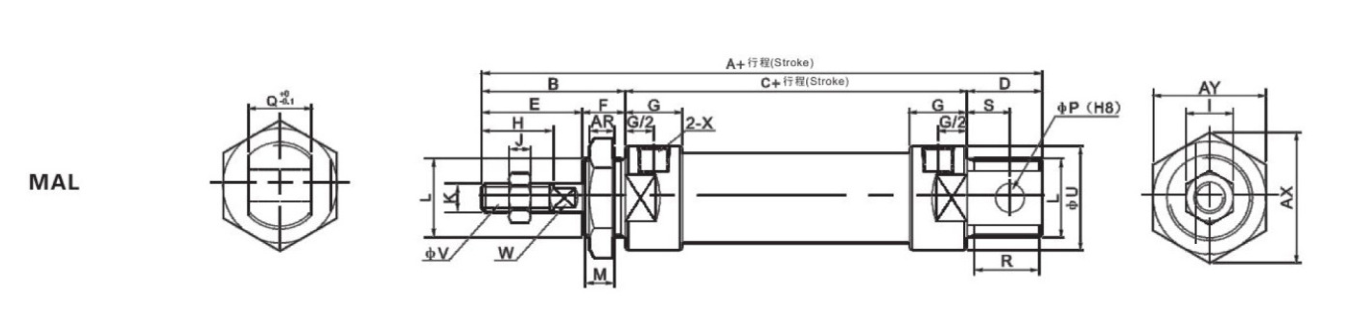

This is the basic outline drawing of a mini cylinder, after installation: standard tail CA installation as long as confirm the size and center point of the P installation hole to the top of the cylinder piston can be replaced

Post time: Oct-29-2021