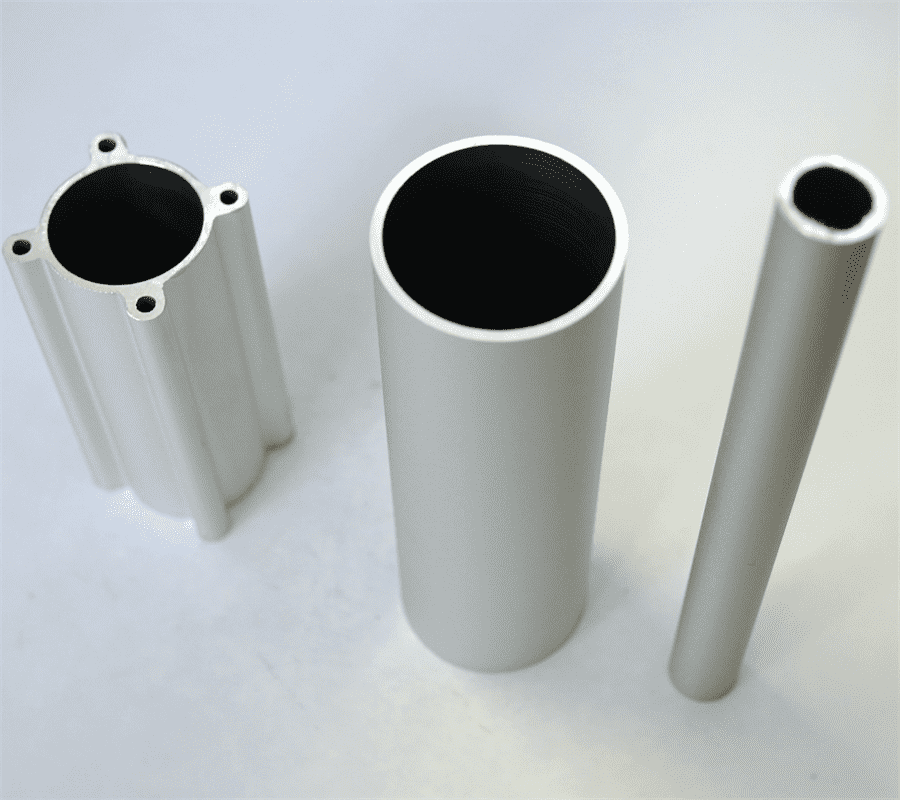

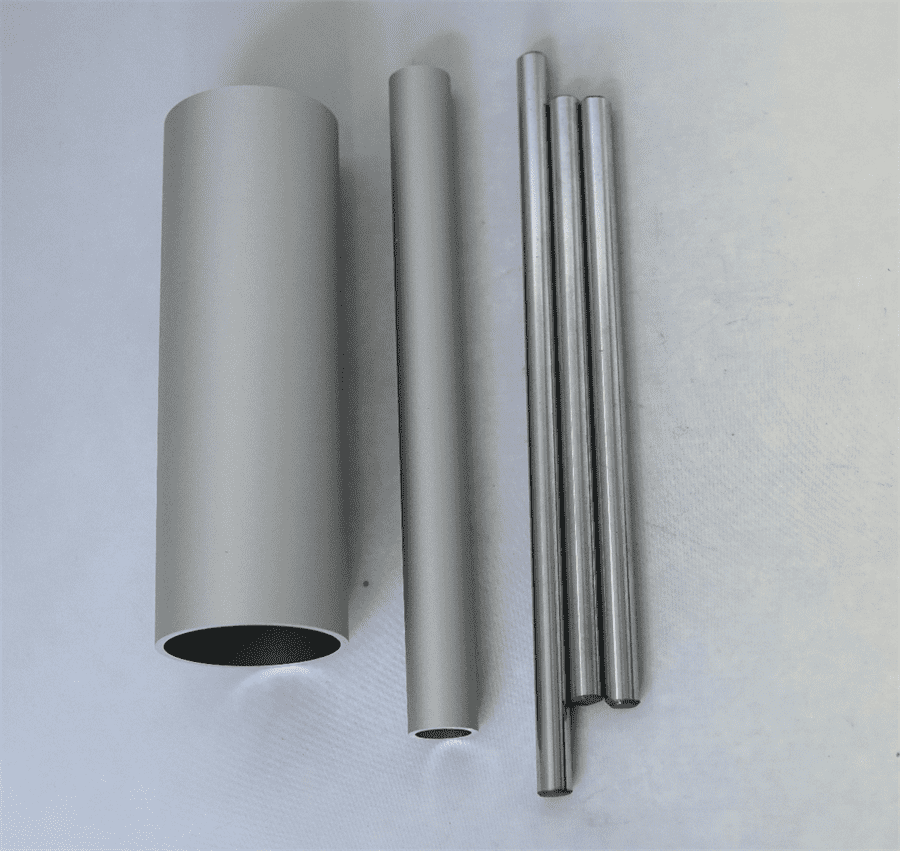

Features: The pneumatic cylinder tube is a high-precision steel pipe material with high precision, high smoothness, resistance to deformation and corrosion resistance. The air cylinder tube made of stainless steel is lightweight and has a long service life. After the aluminum tube is polished, the inner and outer surfaces are as smooth as a mirror. Every pneumatic cylinder tube has been strictly inspected. Scope of application: The aluminum tube is used in the production of various pneumatic cylinders. The cylinder tube is processed by rolling. Because the surface layer leaves the surface residual compressive stress, it helps to close the micro cracks on the surface and hinder the expansion of corrosion. Thereby improving the surface corrosion resistance, and can delay the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the cylinder tube. Through roll forming, a cold work hardened layer is formed on the rolled surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the cylinder tube and avoiding burns caused by grinding. After rolling, the surface roughness value is reduced, which can improve the mating properties. Rolling processing is a kind of chipless processing that uses plastic deformation of metal at room temperature to flatten the microscopic unevenness of the surface of the workpiece so as to achieve the purpose of changing the surface structure, mechanical characteristics, shape and size. Therefore, this method can achieve both smoothing and strengthening purposes at the same time, which cannot be achieved by grinding. No matter what processing method is used for processing, there will always be fine uneven knife marks on the surface of the part, and the phenomenon of staggered undulating peaks and valleys appears.

Post time: Aug-30-2021